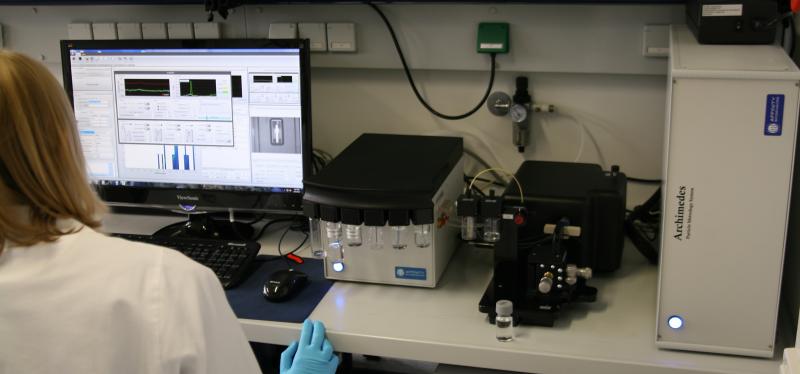

Resonant mass measurement (RMM)

RMM, also known as suspended microchannel resonator (SMR), is a valuable technique for the sizing and quantification of particles.

RMM analysis is based on the Archimedes principle: The upward buoyant force acting on an object in a fluid is equal to the weight of the fluid displaced by the object. The sample solution is flowed through a microchannel inside a resonating cantilever, which resonates mechanically. When a particle passes the embedded channel, the resonation frequency will change proportionally to the particle’s buoyant mass. Positively buoyant and negatively buoyant particles can be clearly discriminated as they, respectively, increase or decrease the frequency of the cantilever. The buoyant mass is then converted into mass and finally into size based on the density of the particle and the density of the fluid. The latter can automatically be determined by the system.

RMM is applicable for particles with a size from about 300 nm to 4 µm, depending on the density difference between particles and fluid. The upper particle concentration limit is roughly 10^7 particles/mL and is method- and sample-dependent.

Particle classification by RMM

One of the main applications for RMM is the quantitative discrimination between silicone oil droplets and protein particles. Such data are crucial for prefilled syringes and cartridges in any development phase, since silicone oil (coated on the glass surface for plunger lubrication) can be present in the product as submicron or micrometer droplets. The differentiation is unambiguous, provided that no other particle type is present in the sample.

RMM is also a valuable orthogonal tool for other particle analytics. Its light-independent measurement principle makes the technique robust against detection issues related to a particle’s refractive index, which are well known for light-based techniques, such as light obscuration [LO], flow imaging microscopy [FIM] and to some extent also for light scattering based techniques, such as dynamic light scattering [DLS] and nanoparticle tracking analysis [NTA].

Quality & biosafety level of this method

We provide all our analytical services with the highest quality standards. Each project is carried out by experienced scientists and every report or data presentation is comprehensively checked by a scientific reviewer. We offer this technology with the following quality and biosafety level:

Standardized methods or dedicated method development

For common sample types, we can often apply standardized methods with little setup effort. On top of this, our experienced analytical scientists perform in-depth method development or method optimization tailored to your drug substance, product type and development phase.

Method development

During method development, we tailor sample preparation, method settings, and data analysis to the needs of your project and sample.

For this purpose, we include a representative sample and, where available, suitable reference standards and stressed/degraded materials. This way, our analytical scientists can design a method that is highly suitable for your needs, stability indicating, as well as robust and repeatable. Upon request, we compile a detailed method description for your records.

This can be applied under R&D. Read more

Method qualification

A method qualification is the initial assessment of the performance of an analytical procedure to show that it is suitable for the intended purpose.

During method qualification, our analytical scientists perform a documented testing that demonstrates that the analytical procedure meets certain acceptance criteria in several categories. These may include repeatability, linearity, intermediate precision, robustness and more. We compile a qualification plan and a qualification report including all relevant data.

This can be applied under R&D. Read more

Contact us

Contact us

Do you have any questions? Want to analyze your samples?