Lyophilization process development

Robust and economical lyophilization processes developed by experts

Lyophilization, also known as freeze-drying, is the process of drying a substance by freezing it followed by sublimation under lower pressure (vacuum). Lyophilization is the method of choice to achieve a stable drug product for many fragile (bio)pharmaceutical molecules. For the development of robust and economical freeze-drying cycles, suitable for large-scale production, we conduct a stepwise development program, tailored to the characteristics of your product and the needs of your development phase.

At Coriolis, we have many years of experience in the development, optimization, scale-up and transfer of lyophilization cycles for (bio)pharmaceutical drug products. Within our lyophilization development center, we operate freeze-dryers from lab to production scale and develop processes for many different biopharmaceutical drug products, including highly concentrated protein formulations, organic solvent containing formulations and drug substances that fall under biosafety level S2 (such as live virus vaccines, viral vectors, etc.)

A comprehensive lyo process development tailored to your product

We offer lyophilization process development tailored to your specific drug substance, development phase and target product profile (TPP), backed by many years of experience with similar drug substances including various solvents and excipients. Click on a product type to explore our entire portfolio of specialized development and analytical services.

Do you have any questions?

Our experts are happy to discuss your questions and inquiries related to lyophilization process development!

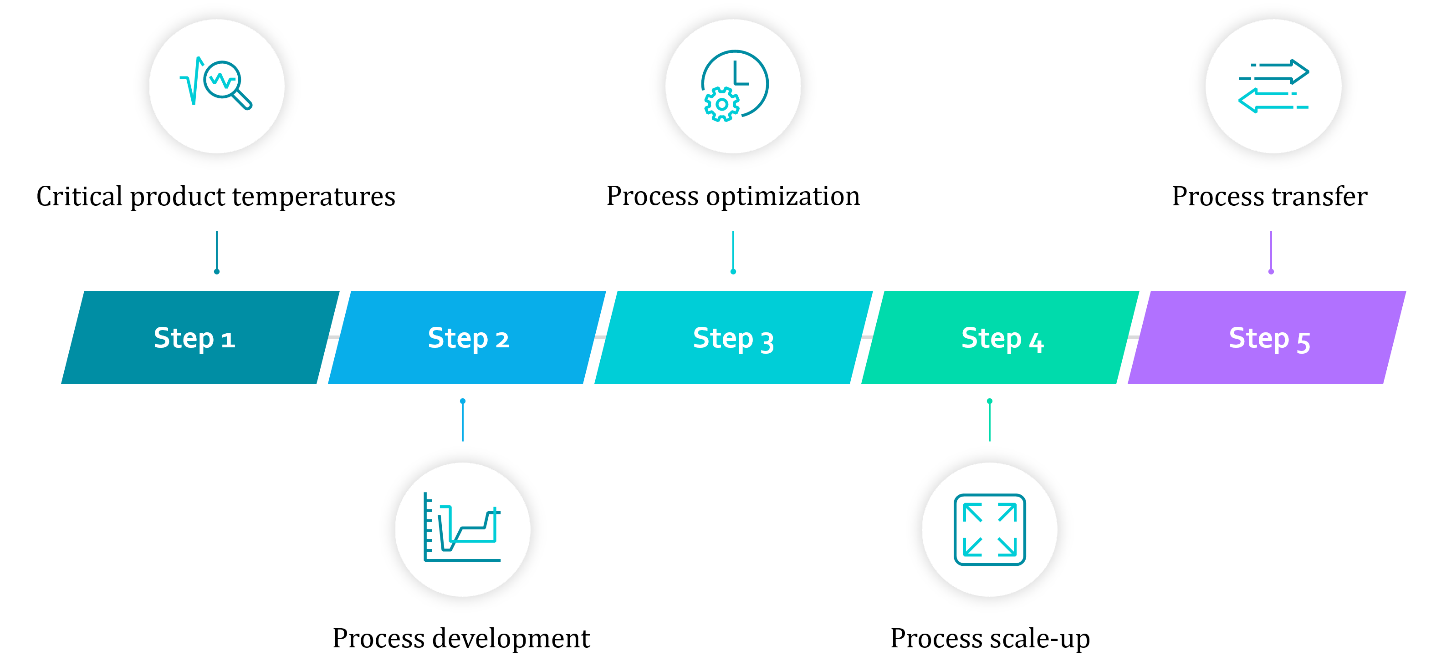

Five steps towards your freeze-drying process

Your road to success takes five steps: determining the critical product temperatures of the drug product, developing an initial freeze-drying process at small scale, optimizing the process by monitoring critical product parameters, scaling the lyophilization process to production scale, and transferring the process to the production site.

From the very beginning, our expert scientists consider the effects and key variables of each freeze-drying step to assure a robust process and to enable a smooth scale-up and transfer to the production facilities.

Process analytical tools and physico-chemical characterization of lyophilizates

At Coriolis, the development of a lyophilized drug product formulation and the corresponding freeze-drying process go hand in hand. Our scientists comprehensively assess the quality of the drug product as well as the success rate of the freeze-drying process in accordance with your expectations. We utilize a large set of process analytical tools (PAT), take in-process samples, and analyze them with a suitable set of physico-chemical characterization methods for lyophilizates. Utilizing this precise procedure not only ensures the robustness of the freeze-drying processes and enables the production of lyophilized drug products of the highest quality, it is also overall time efficient.

Cycle design and optimization

A suitable shelf-life, an elegant cake appearance and an economical lyophilization process are major goals during the development of a freeze-dried (bio)pharmaceutical drug product. Coriolis utilizes a science-based approach for the design and optimization of freeze-drying cycles. This approach is based on the knowledge of critical product temperatures including the collapse temperature (Tc) and the glass transition temperature of the maximally freeze-concentrated solution (Tg´). Based on these temperatures appropriate process parameters are chosen to achieve a robust process, a stable product and economical run times.

Robustness testing, scale up and transfer

The transfer of a lyophilization cycle from Coriolis to the manufacturing site is a crucial step during development. A dedicated lyophilization development center allows our scientists to perform freeze-drying cycle development at lab-, pilot- and production-scale, while optimizing processes for scale-up already at an early development stage. We are committed to design and develop freeze-drying cycles to be robust and scalable, allowing for a smooth and time efficient process transfer.

Quality & biosafety level of this service

We provide all our services with the highest quality standards. Each project is carried out by experienced scientists and every report or data presentation is comprehensively checked by a scientific reviewer. We offer this service with the following quality and biosafety level:

Our Services

Our services related to lyophilization process development

The development of a freeze-drying process needs to go hand in hand with other research, development, and analytical exercises. We typically accompany lyophilization process development with the following services.

Development of a lyophilized formulation

The requirements of a lyophilized formulation are unique. It needs to buffer the drug substance over a large temperature range, provide cryoprotection, stabilize the lyo cake, enable rapid reconstitution and fit the target product profile (TPP).

Therefore, we provide a dedicated formulation development alongside lyophilization process development. With many years of experience in developing lyophilization processes and a strong background in formulation development, Coriolis is your expert partner even for challenging projects.

We offer this service under R&D and up to Biosafety Level S2

Development of analytical methods for lyophilizates

The comprehensive analytical characterization of a freeze-dried drug products is crucial to differentiate a stable from an unstable sample.

Coriolis has a strong expertise in developing methods for analyzing a broad range of lyophilized samples, from peptides and proteins to nucleic acids, virus-like particles and ATMPs, from high concentration antibodies to low concentration hormones, from early-stage drug substance to complex late-stage drug products.

We offer this service under R&D and up to Biosafety Level S2

Our know-how related to lyophilization process development

Coriolis is a science-driven service provider. We perform internal research projects with academic and industrial partners to develop new technologies and create in-depth knowledge, which directly benefits our client projects. Our internal Unit Science & Technology, hosting PhD candidates and Postdocs, also actively contributes to the scientific community with numerous peer-reviewed publications each year. Explore our latest publications, articles, and webinars:

Let's talk!

Find out how you can benefit from a tailored and science-drive lyophilization process development.

Our other services

Coriolis provides a wide range of science-driven and tailor-made solutions for research, development, and analytical challenges. Explore our other services and learn more about how we can support your drug development program. Together, we can make future therapies available to patients and improve the quality of life for humankind.

Contact us

Contact us

Please contact Dr. Matthias Lucke with inquiries related to lyophilization process development

Phone: +49 89 41 77 60 – 253

Mail: matthias.lucke@coriolis-pharma.com