Container closure & integrity testing

Primary packaging materials keep your product safe and enable a secure application

The primary container protects the drug product from external influences, such as direct sunlight, oxygen, moisture, and particulate or bacterial contaminants. But modern primary packaging needs to fulfil several other important tasks, such as enabling simple administration by the healthcare personnel or the patient itself, avoiding the escape of hazardous drugs, and being compatible with other clinical devices such as infusion bags.

Coriolis offers the comprehensive testing of the container closure and the integrity of primary packaging materials, including rubber-stoppered glass vials, prefilled syringes, double-chamber cartridges, application devices, and closed system drug transfer devices (CSTD). We also screen different primary packaging formats and products to identify the most suitable option for your drug product and production process.

Glass vials and rubber stoppers

Glass vials are a commonly used as a versatile primary container for biopharmaceuticals. Both, liquid and lyophilized formulations can be stored, whereas the latter are also freeze-dried directly inside the vial. We utilize a range of analytical techniques, many of them non-invasive, to verify that the oxygen and moisture level inside the headspace of the vial remains unchanged over the intended shelf life and even under accelerated stress conditions following ICH guidelines or custom conditions.

Evaluation of prefilled syringes

Prefilled syringes are often used to enable self-administration by the patient. Elderly people, rheumatoid patients, or children need to be able to use the syringe by themselves but cannot apply large forces on the plunger. We test the break loose and gliding forces of prefilled syringes and double chamber cartridges and compare different syringe and needle combinations to find the most suitable option for your drug product.

Closed system drug transfer devices (CSTD)

The USP <800> “Hazardous Drugs—Handling in Healthcare Settings“ provides standards for safe handling of hazardous drugs and recommends closed systems for administration to minimize the risk of exposure to healthcare personnel, patients and the environment. Regarding injectables, which must be withdrawn from the vial into a syringe and either administered to the patient or transferred to an infusion bag, this refers to closed system drug transfer devices (CSTDs). The National Institute for Occupational Safety and Health (NIOSH) defines a closed system drug-transfer device as “a drug transfer device that mechanically prohibits the transfer of environmental contaminants into the system and the escape of the hazardous drug or vapor concentrations outside the system”. We follow comprehensive protocols when testing closed system transfer devices for their ability to protect healthcare workers as well as the drug product.

Do you have any questions?

Our experts are happy to discuss your questions and inquiries related to container closure & integrity testing!

Testing container closure and integrity for your drug product

We offer container closure & integrity testing for the following product types. This service is based on our broad scientific experience with a large variety of biopharmaceutical drug products. We will tailor each project to your specific product type, primary container, and development phase. Click on a product type to explore our entire portfolio of specialized analytical and development services.

Quality & biosafety level of this service

We provide all our services with the highest quality standards. Each project is carried out by experienced scientists and every report or data presentation is comprehensively checked by a scientific reviewer. We offer this service with the following quality and biosafety level:

From generic to custom analytical methods and beyond

We offer a large selection of generic analytical methods for many common applications or develop custom methods specific for your needs. Our expert scientists also perform a method feasibility to assess, which technique is most suitable for your request. We offer the following options:

Methods ready to use

Our expert scientists have established generic analytical methods for many common applications. This guarantees a quick turnaround for sample testing and reduces the need for method adjustments to a minimum.

We suggest generic methods for your sample based on our many years of experience with similar products and analytical questions. If you reach a development stage, where fully developed and documented methods are required, we can build upon our expertise in customizing and optimizing any analytical method.

This is available for a selection of analytical techniques.

Method development

During method development, we tailor sample preparation, method settings, and data analysis to the needs of your project and sample.

For this purpose, we include a representative sample and, where available, suitable reference standards and stressed/degraded materials. This way, our analytical scientists can design a method that is highly suitable for your needs, stability indicating, as well as robust and repeatable. Upon request, we compile a detailed method description for your records.

This can be applied to all our techniques (R&D and GMP). Read more.

Method qualification

A method qualification is the initial assessment of the performance of an analytical procedure to show that it is suitable for the intended purpose.

During method qualification, our analytical scientists perform documented testing to establish and assess acceptance criteria in several performance characteristics. These may include repeatability, linearity, intermediate precision, robustness and more. We compile a qualification plan and a qualification report including all relevant data.

This can be applied to all our techniques (R&D and GMP). Read more.

Our know-how related to container closure & integrity testing

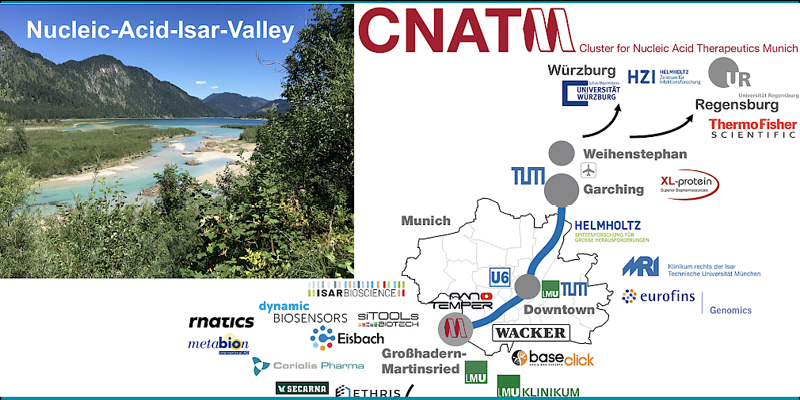

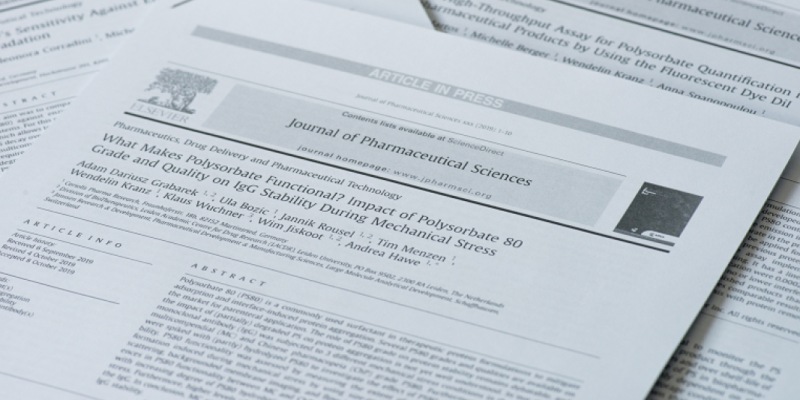

Coriolis is a science-driven service provider. We perform internal research projects with academic and industrial partners to develop new technologies and create in-depth knowledge, which directly benefits our client projects. Our internal Unit Science & Technology, hosting PhD candidates and Postdocs, also actively contributes to the scientific community with numerous peer-reviewed publications each year. Explore our latest publications, articles, and webinars:

Let's talk!

Do you have questions to our container closure & integrity testing? Need a quote for one of our techniques?

Our other services

Coriolis provides a wide range of science-driven and tailor-made solutions for research, development, and analytical challenges. Explore our other services and learn more about how we can support your drug development program. Together, we can make future therapies available to patients and improve the quality of life for humankind.

Contact us

Contact us

Please contact Dr. Matthias Lucke for inquiries related to container closure & integrity testing

Phone: +49 89 41 77 60 – 253

Mail: matthias.lucke@coriolis-pharma.com