Scanning electron microscopy coupled energy-dispersive x-ray spectroscopy (SEM-EDS)

Visualization and identification of samples by SEM-EDS

SEM-EDS combines the benefits of two valuable analytical techniques:

- Scanning electron microscopy (SEM), a versatile visualization technique

- Energy-dispersive x-ray spectroscopy (EDS), a powerful technique for elemental analysis

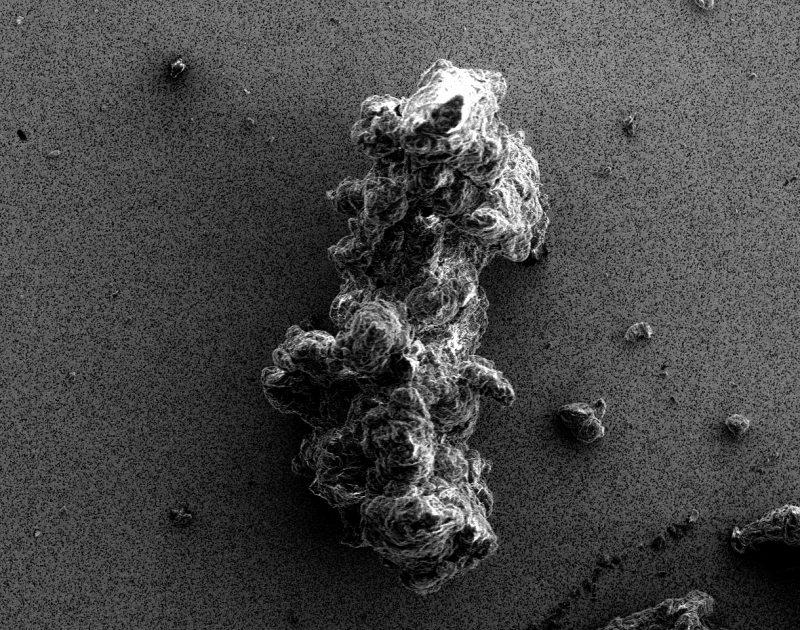

During SEM analysis, the surface of a specimen is scanned in a raster pattern with an electron beam. Atoms on the sample surface interact with the electron beam and emit secondary electrons (SE) from their own shell as well as back-scatter electrons (BSE) from the beam itself. SE- and BSE-detectors collect and process the electron signals and allow for a visualization of the sample surface down to the nanometer scale.

SEM usually operates at a high vacuum and with a high electron beam voltage to achieve a maximum resolution. This requires the sample to be electrically conductive. If this is not the case, sample need to be coated with a conductive material, e.g., by sputter coating or by high vacuum evaporation.

Non-conductive specimen, such as biological samples, may be measured without coating by reducing the electron beam voltage and by applying only a low or no vacuum. While this reduces image resolution, it can omit potential alteration of the sample during preparation.

Energy-dispersive x-ray spectroscopy (EDS)

When secondary electrons are emitted from the sample upon interaction with the electron beam, higher energy electrons will fill their position and emit energy in form of X-rays. These X-rays are characteristic for the element from which they were emitted and can thus be used to map the elemental composition on the surface of a specimen. This information is very valuable to determine the chemical identity and origin of a specimen.

Applications of SEM-EDS include:

- Visualization of subvisible particles isolated from liquid samples

- Elemental analysis of subvisible particles isolated from liquid samples

- Inspecting the structure and physical state of lyophilized products

Coriolis offers SEM-EDS as a standalone service or as part of a formulation development program (liquid and lyo), lyophilization process development, or during troubleshooting and root-cause analysis.

Contact us

Contact us

Need more information? We are happy to answer your questions!